Introduction

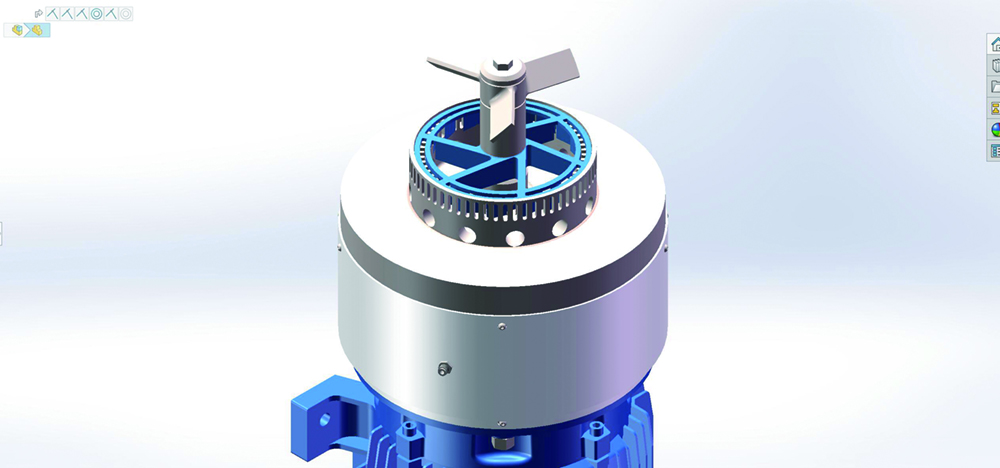

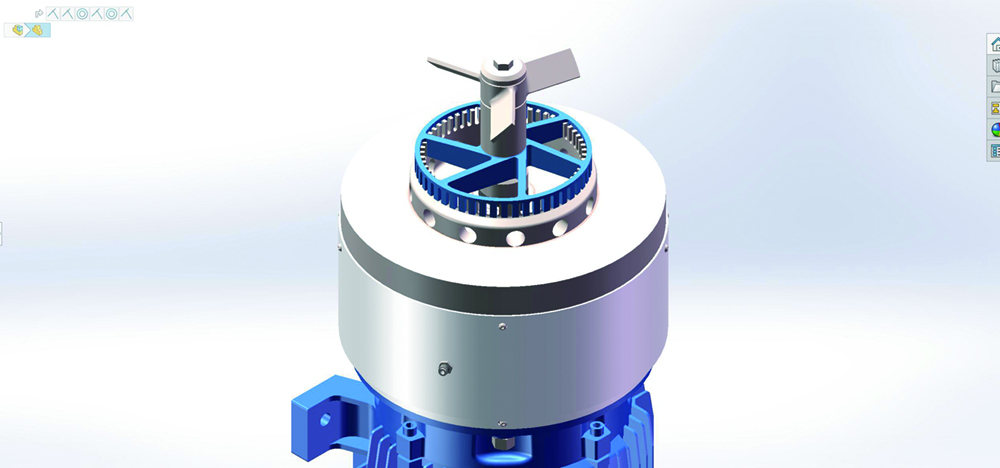

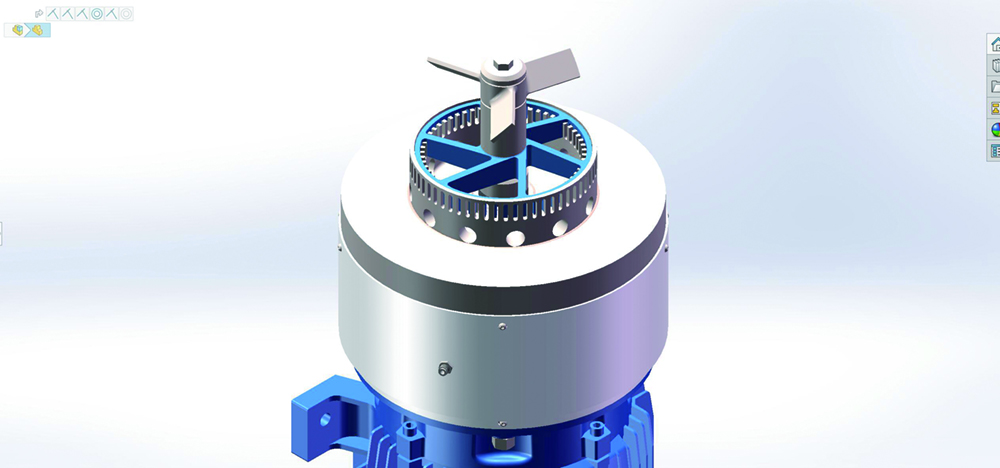

BEE bottom entry emulsifier – High shear and high flow in a simple, compact and sanitary design.

BEE bottom entry emulsifier are installed in the bottom of the tank and capable of carrying out product dispersing,mixing, emulsifying and homogenizing.

Depending on application, with different types of rotor/stator tooling combinations, BEE can generate the ideal particle size for stable emulsions and homogeneous final products.

BEE can be used in an agitator system fitted with an anchor impeller for high viscosity products, or can work alone if the product has low viscosity.

Features

- Sanitary design

- Rotor/Stator are machine from solid bar or forged materials

- 316L for wetted parts, optional 2205, 2507, Hastelloy etc.

- Reduce air intake significantly

- Helps to prevent appearance of vortices

- Can be used for most demanding dispersing and homogenizing tasks

- Low starting liquid level and small batch capability

- Low level dissolving gels to reduce whole process time

- Different rows of rotor/stator combinations

- Different slot size for rotor/stator tooling

- Optional additional high flow impeller

- Standard cartridge type double mechanical seal

- CIP and SIP capable

- Operating pressure up to 10 bar

- Operating temperature up to 121 ℃

Applications

The sanitary design of BEE makes it best suited for beverage, food, pharmaceutical, biotech, cosmetic, personal care, dyes, chemical and industrial

- Dissolving various gels

- Fast dispersing solids with liquids

- Pharmaceutical blending

- General dispersion

- De-agglomeration

- Accelerated dissolution

- Particle size reduction

- Homogenization

- Emulsification

- Reaction acceleration

Specifications and Model

| Model | Power Range | Speed | Rotor/Stator | Hyflow Propeller | Max. Tank Volume | Tank Flange |

|---|---|---|---|---|---|---|

| BEE15 | Max.11 kw | 3000 rpm | Yes | No | 1,000 liters | DN150 |

| BEE15P | Max. 22 kw | 3000 rpm | Yes | Yes | 1,500 liters | DN150 |

| BEE30 | Max.22 kw | 1500 rpm | Yes | No | 5,000 liters | DN250 |

| BEE30P | Max.30 kw | 1500 rpm | Yes | Yes | 10,000 liters | DN250 |