Introduction

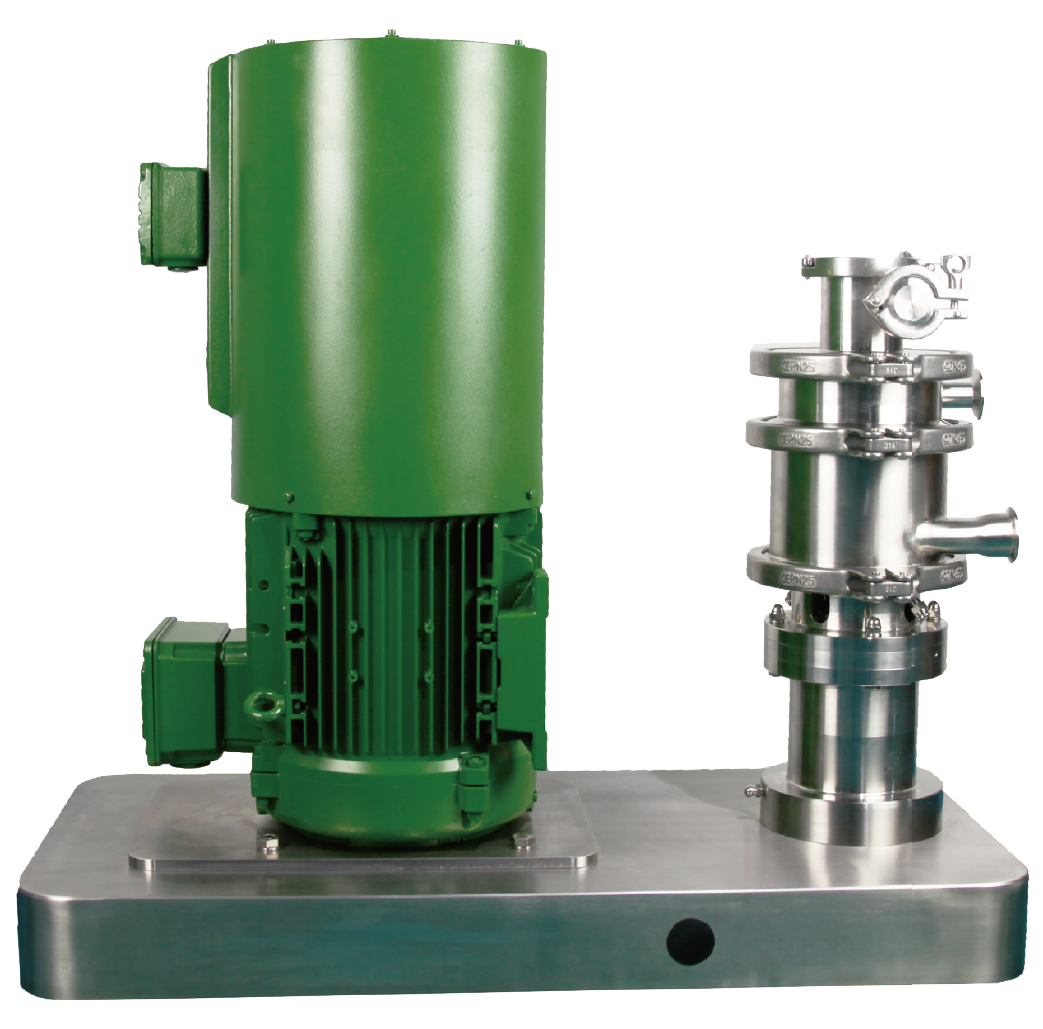

CME series are capable of from cutting and breaking to fine grinding in one machine. When mainly for cut and mill application, CME series are normally equipped with controlled inlet liquid flow and metered dry solids flow. For high water content raw material, it can cut and mill without addition of water.

CME series are also designed for emulsion application, with final liquid droplet size or emulsion reaching or even exceeding 1μm. Thanks for its high peripheral speed, you can easily change tooling combination for emulsifying and homogenizing application.

CME series can be fed with lobe pump, hopper, metered feed screw etc.

First cut and grinding tools are equipped with different discs and knife selection. Knife with pre cutter is standard. First stage clearance is adjustable between knife and perforated disc by using different size of shim. Second milling and emulsifying tools are assembled with different tooth shape or tooling slot size range from 0.5mm to 6mm.

Features

- Sanitary design, CIP and SIP capable

- Very slight temperature rise

- Reduce process time consumption

- Good for slurry making when using SCC for flavor extraction

- Good for slurry making when using SCC for flavor extraction

- From lab to production, excellent reproducibility guaranteed

- From lab to production, excellent reproducibility guaranteed

- Consistent high-quality products across different production batches

- Consistent high-quality products across different production batches

- Reduce particle size and other functions

- Controlled, uniform particle or droplet size

- Inlet particle size up to 10mm

- 316L for wetted parts, optional 2205, 2507, Hastelloy etc.

- 316L for wetted parts, optional 2205, 2507, Hastelloy etc.

- Cut knife and disc made from high strength and wear resistant materials

- Rotor/stator are machined from solid bar

- CME casing are all machined from bar or forged

- raw materials

- Different rows and slot size for rotor/stator tooling

- Standard cartridge type double mechanical seal

- Optional Jacketed housing

- Optional CIP port for better cleaning

Applications

With different knife and tooling combination, you can actually o ptimize your current process system.Processing steps, including cutting, chopping, grinding, pulpin g, mashing, emulsifying, dispersing and homogenization are performed within one units.

- Coffee slurry making

- Tea slurry making

- Apple slurry making

- Soy bean milling with water

- Ginger slurry making

- Plum slurry making

- Cucumber slurry making

- Various vegetable slurry making

- Fruit juices, smoothie or slurry

- Sauces and dressings

- Meat/fish paste

- Animal organs, offal

- Suspensions

- Ointments

- Tablet coatings

- Pesticides

- Various emulsions

Specifications and Model

| Model | Power Range | Flow Rate | Liquid Inlet | Solids Inlet | Liquid Outlet | Stage | Installation |

|---|---|---|---|---|---|---|---|

| CME06 | Max. 7.5kw | Max.3 m3/h | 1.0″ | 3.0″ | 1.5″ | Single or Double | Vertical |

| CME15 | Max. 18.5kw | Max.10 m3/h | 1.5″ | 4.0″ | 2.0″ | Single or Double | Vertical |

| CME30 | Max. 45kw | Max.25 m3/h | 2.0″ | 8.0″ | 3.0″ | Single or Double | Vertical |