Introduction

DIB series are designed for dynamic inline blending and mixing. Stator less design model is suitable for soft inline mixing, used for mixing large particles, shear sensitive materials, fibrous materials (without entanglement), high solid content materials, gas containing materials, etc. According to the application, different rotor designs and speeds can be selected to ensure a uniform and consistent final mixture after mixing.

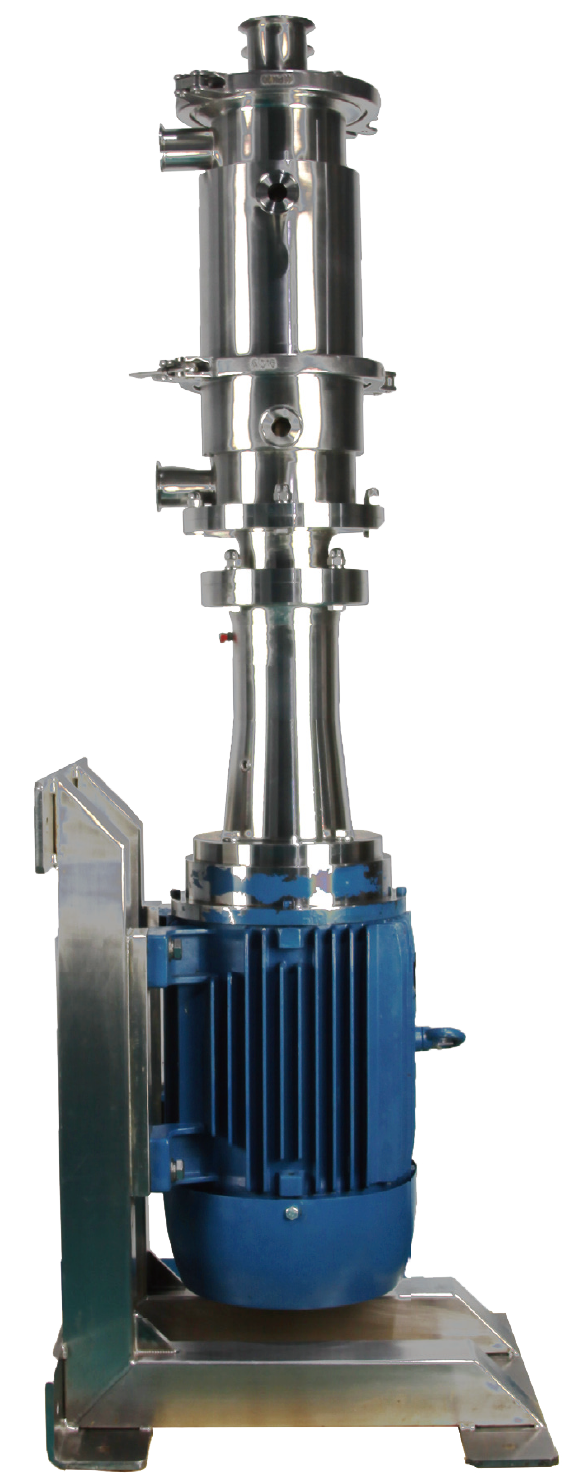

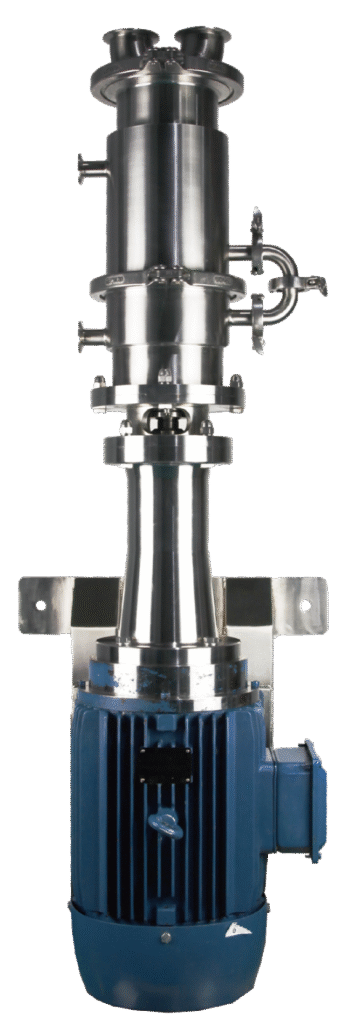

The rotor/stator design model is suitable for medium to ultra-high strength inline mixing, such as the preparation of baking fillings, mixing jam in yogurt, mixing chocolate and nuts, etc. Both the stator and rotor are designed for easy disassembly, allowing for inline cleaning and sterilization. The geometry and number of stages of the stator and rotor are determined by different mixing requirements, and the clearance between the stator and rotor is generally standard, but can also be customized according to mixing needs. The installation form can be vertical installation or horizontal installation. Vertical installation can be driven by a belt or directly connected to the motor through the spindle housing.

The cylindrical design of the mixing unit can effectively control the temperature rise during the mixing process. Multiple inlets can be designed and arranged according to process needs. Various hygienic sensor ports can also be installed on the casing. Modular design ensures the interchangeability of stator and rotor assembly between different shapes. Skid unit system can be designed to fulfill complete functional requirements from product pumping, metering, mixing, piping, instrumentation to automation control.

Features

- Sanitary design, CIP and SIP capable

- From lab to production, excellent reproducibility guaranteed

- Consistent high-quality products across different production batches

- Controlled, uniform end products

- 316L for wetted parts, optional 2205, 2507, Hastelloy etc.

- Rotor/stator/casing are normally machined from solid bar or forged raw materials

- Mixing stage start from 3, up to 16 stages

- Versatile rotor/stator combination

- Standard cartridge type double mechanical seal, single seal optional

- Optional Jacketed housing for heating or cooling

- The standard casing design pressure is 10 bar. for higher pressures, please consult

Applications

DIB series dynamic inline blender is suitable for low to high viscosity mixing. Basic model start with very delicate and no damage blending. By change motor speed and rotor/stator combinations, DIB series are capable of strong blending of high viscosity materials, mixing large quantity solids with heavy liquids and dispersing gas within liquids continuously.

- Flavor addition

- Various additive addition

- Preparation of baking fillings

- Mixing jam in yogurt

- Mixing chocolate and nuts Prepared foods

- Processed cheese

- Ice cream

- Dressings, Sauces & Dips

- Butter & Margarine

- Polymer addition

- Adhesive and sealants Paints, inks and coatings

Specifications and Model

| Model | Power Range | Flow Rate | Liquid Inlet | Powder Inlet | Liquid Outlet | Stage | Installation |

|---|---|---|---|---|---|---|---|

| DIB06 | Max. 7.5kw | Max.3 m3/h | 1.5″ | 2.5″ | 1.5″ | Up to 10 stage | Vertical/Horizontal |

| DIB15 | Max. 15kw | Max.10 m3/h | 2.0″ | 3.0″ | 2.0″ | Up to 16 stage | Vertical/Horizontal |

| DIB30 | Max. 30kw | Max.30 m3/h | 3.0″ | 4.0″ | 3.0” | Up to 16 stage | Vertical/Horizontal |